The shock-resistant pressure gauge is also composed of multiple parts such as joints, spring tubes, seals, movement, connecting rods, dials (dials), pointers, seals, and casings.

Some pointer materials should be made lighter and more flexible to avoid bending and deformation of the pointer when the instrument suddenly drops to a low position or is subjected to a strong collision.

When the pointer is centered on the needle cap, the indicating end and the tail end should be in a static balance state, otherwise the instrument value will be distorted and the instrument accuracy will be reduced.

The riveting between the pointer and the needle cap should be firm to avoid loosening. The taper of the inner hole of the needle cap must be consistent with the taper of the central axis of the movement to ensure that the pointer and the movement shaft are tightly combined and prevent the pointer from falling off during operation.

The indicating part of the pointer should cover 1/4 to 1/3 of the length of the short scale.

When the dial color is white, the front of the pointer is black or blue; when the dial is black, the front of the pointer is white or yellow. The pointer is not allowed to reflect light, so as not to interfere with the reading.

The pointer must not have defects that affect the appearance and shape, such as paint peeling, interlayer, burrs, etc.

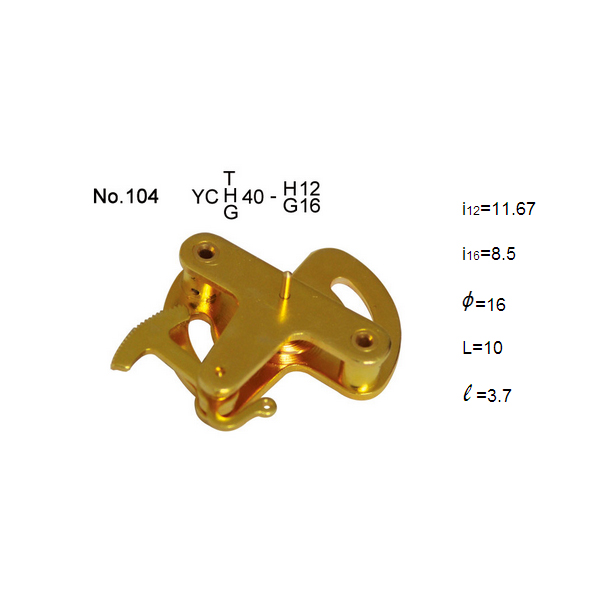

2.5 Inch 60mm Brass Pressure Gauge Assembling Movement

Φ—Signify center distance of assembling movement's mounting groove.

L—Signify the length of needle pivot (which means shaft gear).

Product Name; Bimetallic Assembling Movement

Material: Brass/stainless steel 304

Transmission ratio: 14/ 11.86 /9

Movement's shaft gear: 12/14/18

Certificate: ISO9001; ISO14001

Used: Pressure gauge